Elevate product reliability with optical measurement during final inspection stages

Elevate product reliability with optical measurement during final inspection stages

Blog Article

Discovering the Applications of Optical Dimension Equipments in Numerous Industries

You could not recognize exactly how vital optical dimension systems are throughout different industries. They boost accuracy in manufacturing, improve diagnostics in medical care, and guarantee security in aerospace. These systems are reinventing exactly how you regard top quality and effectiveness. What does the future hold for these innovations? Discovering their applications reveals not simply existing benefits however additionally interesting potential improvements on the horizon.

Optical Dimension Equipments in Manufacturing

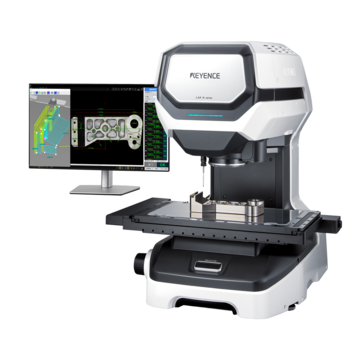

As producing processes become increasingly complex, optical dimension systems play a vital duty in assuring accuracy and efficiency. You rely upon these systems to enhance quality assurance, simplify manufacturing, and reduce waste. By making use of sophisticated imaging strategies, you can accurately gauge dimensions, surface area profiles, and even material residential properties in real-time.

These systems help you recognize issues early in the production process, permitting for quick adjustments and reducing costly errors. Whether you remain in automotive, aerospace, or electronic devices, optical dimension systems adjust to your particular requirements, enhancing your process and performance.

Additionally, their non-contact nature warranties that fragile parts continue to be unscathed during evaluation. Applying these innovations not just enhances your operational capacities but additionally elevates the total quality of your items. In a sector where precision is paramount, optical measurement systems provide the advantage you need to remain competitive and fulfill requiring standards.

Enhancing Healthcare Diagnostics With Optical Technologies

Optical technologies are changing medical care diagnostics, similar to they have actually transformed producing processes. You can see exactly how these developments allow quicker, extra precise disease detection and tracking. Optical coherence tomography (OCT) gives high-resolution pictures of the retina, permitting for very early detection of conditions like glaucoma and diabetic retinopathy.

Moreover, fluorescence microscopy can help you determine certain cellular pens, enhancing cancer cells diagnostics. With non-invasive methods like optical spectroscopy, you have the ability to analyze cells properties, using real-time understandings without the requirement for biopsies.

These technologies not just boost client results but likewise improve process in professional settings. By integrating optical measurement systems right into diagnostics, you're making sure an extra efficient approach to health care. As these technologies remain to advance, you can anticipate also higher improvements in precision medication, bring about tailored treatments that deal with private patient demands.

The Role of Optical Measurement in Automotive Industries

In the automotive market, accuracy in component manufacturing is crucial for safety and efficiency. You'll discover that optical measurement innovations play a necessary function in making certain quality assurance and assurance throughout the manufacturing process. By incorporating these systems, producers can improve accuracy and decrease errors, eventually resulting in much better automobiles.

Accuracy in Element Manufacturing

You count on optical measurement systems to assure every element satisfies rigorous specs. By integrating optical dimensions right into your production processes, you can lower errors and lessen waste, inevitably conserving time and cash. With optical measurement, you improve the reliability of your parts, guaranteeing they do at their finest in the demanding automotive environment.

Quality Assurance and Guarantee

Quality assurance is an important facet of automobile production, making certain that every component fulfills rigid safety and security and performance requirements. By incorporating optical dimension systems, you can enhance your top quality guarantee procedures substantially. These systems offer exact, non-contact dimensions that aid find flaws and variants in elements swiftly. With real-time information, you can make enlightened decisions, decreasing the danger of defective components getting to the setting up line. Optical dimension additionally helps in confirming dimensions and surface qualities, guaranteeing they line up with specifications. And also, the automation of these processes lessens human error, enhancing overall effectiveness. Inevitably, utilizing optical dimension systems not only increases item quality however also reinforces your brand name's credibility in an affordable market.

Optical Systems in Aerospace and Defense Applications

In aerospace and defense, optical systems play a necessary duty in ensuring safety and security and efficiency. You'll discover accuracy measurement techniques and structural integrity evaluations vital for keeping airplane and military devices. Plus, real-time surveillance systems improve situational recognition, making them indispensable in today's defense strategies.

Accuracy Measurement Strategies

While lots of markets rely on different measurement strategies, the aerospace and protection markets demand incredibly high standards for accuracy and integrity. In these areas, precision dimension techniques utilizing optical systems play an essential role. These optical approaches not only enhance dimension precision but likewise improve effectiveness by reducing the time navigate here needed for evaluations.

Structural Integrity Analysis

As you evaluate architectural honesty in aerospace and defense applications, optical measurement systems prove vital. These systems offer exact, non-contact methods for evaluating the condition of critical elements, ensuring safety and security and integrity. By making use of methods like laser scanning and interferometry, you can identify minute deformations and anxiety concentrations that might compromise structural stability. This real-time information assists you make informed choices concerning maintenance and repairs, inevitably prolonging the life-span of aircraft and army devices. Additionally, the capacity to imagine information in three measurements improves your understanding of possible failing factors. By integrating these optical systems into your assessment procedures, you're not only boosting precision however likewise improving overall operational effectiveness sought after aerospace and defense environments.

Real-Time Surveillance Solutions

Building on the significance of optical dimension systems for architectural integrity, real-time monitoring systems play an essential duty in improving situational understanding in aerospace and defense applications. These systems make use of advanced optical modern technologies, including high-resolution you can try these out video cameras and LiDAR, to monitor environments continually. You can track possible hazards, analyze mission-critical operations, and assurance safety by integrating these systems right into aircraft and ground lorries. Real-time data evaluation permits fast decision-making, adapting to swiftly transforming scenarios. Optical monitoring aids in reconnaissance missions, providing detailed images and understandings without endangering security. By welcoming these modern technologies, you're not just boosting functional performance yet also enhancing defense abilities in an ever-evolving landscape.

Developments in Optical Dimension for Environmental Surveillance

Optical measurement technologies have actually significantly advanced, boosting our capability to keep an eye on ecological adjustments with unprecedented precision. You can currently leverage progressed sensors that utilize light to discover air quality, water purity, and even biodiversity. These systems provide real-time information, enabling you to respond swiftly to environmental dangers.

For example, remote noticing techniques allow the evaluation of logging and urban spread, utilizing satellite imagery to track changes over time. Spectroscopy approaches have enhanced your ability to identify toxins at minute concentrations, making certain conformity with ecological regulations.

Furthermore, innovations in LiDAR innovation enable for exact topographic mapping, essential for flooding risk management and environment conservation. By incorporating these optical dimension systems into your environmental monitoring approaches, you'll acquire useful insights that drive informed decision-making and advertise sustainability. Welcoming these technologies can equip you to protect our world better than ever previously.

Optical Measurement Solutions in Electronic Devices and Semiconductor Industries

In the hectic globe of semiconductors and electronics, leveraging advanced optical measurement options can considerably improve making procedures and item high quality. These systems enable you to analyze essential parameters such as density, surface roughness, and feature sizes with outstanding accuracy. By utilizing methods like laser triangulation and interferometry, you can find minute defects that conventional techniques might miss out on.

Implementing optical dimension solutions helps enhance assembly line, ensuring that your products meet rigid top quality criteria (optical measurement). You'll discover that real-time information collection promotes fast changes, minimizing waste and lessening rework. Additionally, these systems can be integrated into automated operations, enhancing general efficiency

As you embrace optical dimension innovations, you'll reinforce your one-upmanship in a swiftly evolving market. The accuracy and dependability these solutions supply not just enhance item efficiency however additionally reinforce your online reputation for quality, making them essential in the electronics and semiconductor sectors.

Future Patterns and Technologies in Optical Dimension Equipments

As sectors remain to embrace advanced modern technologies, the future of optical measurement systems looks promising. You'll see advancements in man-made intelligence and maker knowing enhancing information analysis, allowing much faster and much more exact measurements. Real-time monitoring will certainly come to be typical, enabling instant changes in producing procedures.

Miniaturization of sensors will certainly additionally play a crucial function, making optical systems much more available and mobile for numerous applications. Anticipate technologies in 3D imaging and holography to change high quality control, supplying deeper understandings into item stability.

Sustainability will certainly drive the advancement of green optical measurement services, lowering waste and energy usage. In addition, combination with the Internet of Things (IoT) will facilitate smooth information exchange, leading the way for smart manufacturing.

Frequently Asked Questions

What Are the Key Elements of Optical Dimension Equipments?

The secret components of optical measurement systems include source of lights, filters, detectors, and lenses. You'll locate that these aspects interact to record and evaluate information precisely, making certain exact measurements in numerous applications.

Just How Do Optical Dimension Equipments Compare to Standard Measurement Methods?

Optical measurement systems provide greater precision and rate compared to conventional methods. You'll notice they minimize human error, offer non-contact alternatives, and help with intricate dimensions, making them a smarter option for precise data collection.

What Industries Are Becoming Individuals of Optical Measurement Technologies?

You'll locate arising markets like aerospace, Continue automotive, and healthcare significantly taking on optical measurement innovations. These sectors take advantage of improved precision and performance, driving technology and enhancing top quality in their procedures and products. It's rather interesting!

What Are the Expense Ramifications of Implementing Optical Measurement Solutions?

Executing optical measurement systems can be expensive in advance, but you'll usually see long-lasting financial savings from enhanced accuracy and efficiency. You'll likewise minimize waste and enhance item high quality, resulting in much better client contentment and higher revenues.

Exactly How Can Companies Ensure Accuracy and Reliability in Optical Measurements?

To guarantee precision and reliability in optical dimensions, you must consistently calibrate your tools, train operators thoroughly, keep a regulated environment, and utilize top notch elements. These actions decrease errors and boost dimension uniformity.

Final thought

Ultimately, optical measurement systems are reinventing multiple industries by enhancing accuracy and efficiency. Welcoming optical measurement systems now can establish you apart in today's competitive landscape.

As manufacturing procedures end up being progressively complicated, optical dimension systems play an essential role in ensuring accuracy and effectiveness. By integrating optical dimension systems, you can boost your quality assurance procedures substantially. Eventually, making use of optical dimension systems not just boosts product quality but likewise enhances your brand name's track record in a competitive market.

Structure on the significance of optical dimension systems for structural stability, real-time monitoring systems play a crucial duty in boosting situational recognition in aerospace and defense applications - optical measurement systems. Just How Do Optical Measurement Systems Contrast to Conventional Measurement Methods?

Report this page